-edible zone-

-- This turntable arrived less bottom plate, less tonearm and less armboard. That's ok. I mean to change those items.

* Serial #79209, 60 hz, 2/4 Watts

Serial #79209, 60 hz, 2/4 Watts

* (click thumbnail for full size image)

(click thumbnail for full size image)

-- When spending my own money on a used turntable, I want to know about the condition of the platter bearing. The photos don't do this spindle shaft justice. The part is nearly mint showing only slight evidence of wear at the upper bushing area. This is normal. It is where the driving force occurs and also where the bearing is likely to have the least amount of lube.

*

* (click thumbnail for full size image)

(click thumbnail for full size image)

-- This bearing housing looks the same as that used on the TD160 and TD125 Mk II. But those tables didn't get the captive ball tip in the spindle shaft. I should also note that the TD125 mk1 did get the bearing ball tip, but it had a different bolt-in bearing housing, whereas the bearing housing seen here is of the 'press-in' variety and was used on several models including all of the TD14x and TD16x models

*

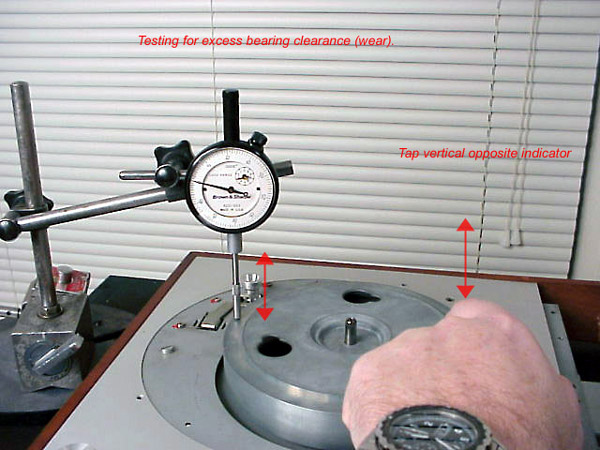

-- Using a dial indicator to test bearing clearance by tapping vertically on the opposite face of the subplatter. Reading was less than .0005 inches. Also checked face run-out by spinning subplatter. Reading was .0015 inches. Note: bearing was dry for this test.

* Dial indicator test for bearing clearance by tapping

horizontally on subplatter opposite the indicator. Reading was

less than .0005 inches. Also checked circular

run-out by rotating the platter. Circular runout read was .0015

inches. Note bearing was dry for this test.

Dial indicator test for bearing clearance by tapping

horizontally on subplatter opposite the indicator. Reading was

less than .0005 inches. Also checked circular

run-out by rotating the platter. Circular runout read was .0015

inches. Note bearing was dry for this test.

* Another critical area is the motor, shaft and pulley. Note belt residue

on the lower pulley land. This is common for a Thorens.

Their belts tend to leave deposits. The rubber deposits clean off

with alcohol and Q-tip. Otherwise note the pulley

is nicely machined from solid aluminum which is as good as it gets.

The steel post sticking out horizontally is there to act as a belt guide when

shifting between 33 and 45. Btw, the TD16x models had plastic

pulleys and could be disassembled from the motor. This solid

aluminum pulley must be pressed or pulled off using machine shop presses

and pullers.

Another critical area is the motor, shaft and pulley. Note belt residue

on the lower pulley land. This is common for a Thorens.

Their belts tend to leave deposits. The rubber deposits clean off

with alcohol and Q-tip. Otherwise note the pulley

is nicely machined from solid aluminum which is as good as it gets.

The steel post sticking out horizontally is there to act as a belt guide when

shifting between 33 and 45. Btw, the TD16x models had plastic

pulleys and could be disassembled from the motor. This solid

aluminum pulley must be pressed or pulled off using machine shop presses

and pullers.

--Further notes on motor shafts. It is not uncommon to find a bent motor shaft on this and other Thorens belt-drive models. The problem area is with the outer platter, while it is being lifted off by inexperienced hands, and being allowed to swing into heavy contact with the motor pulley. Typically a bent motor shaft will result. Motors are no longer available for this model except as 2nd hand or in the rare case, NOS. It won't be cheap to replace. Beware.

--#

--Run the motor. Check for two things: 1) that the motor shaft has not been bent. It should spin absolutely true. 2) Check that it runs quietly as follows: Using a mechanic's stethoscope, probe next to the motor at the motor plate. Listen. Very quiet, thank you. Just a light whirr. Not audible without the stethoscope. Move the probe further away from the motor and listen again. Nothing. Good.

.

*

-- No heavy damage evident anywhere. No dings, dents or scratches in

the platters. Light scuffing on the top facia. Some apparent scuffing

and chipping around the edges of the veneer cabinet. Bearing looks

really good and shows very little wear for its 30 plus years. Motor runs

quiet and the drive pulley spins true.

Seems like a good one to

me. On to disassembly and clean up and more detail inspection.